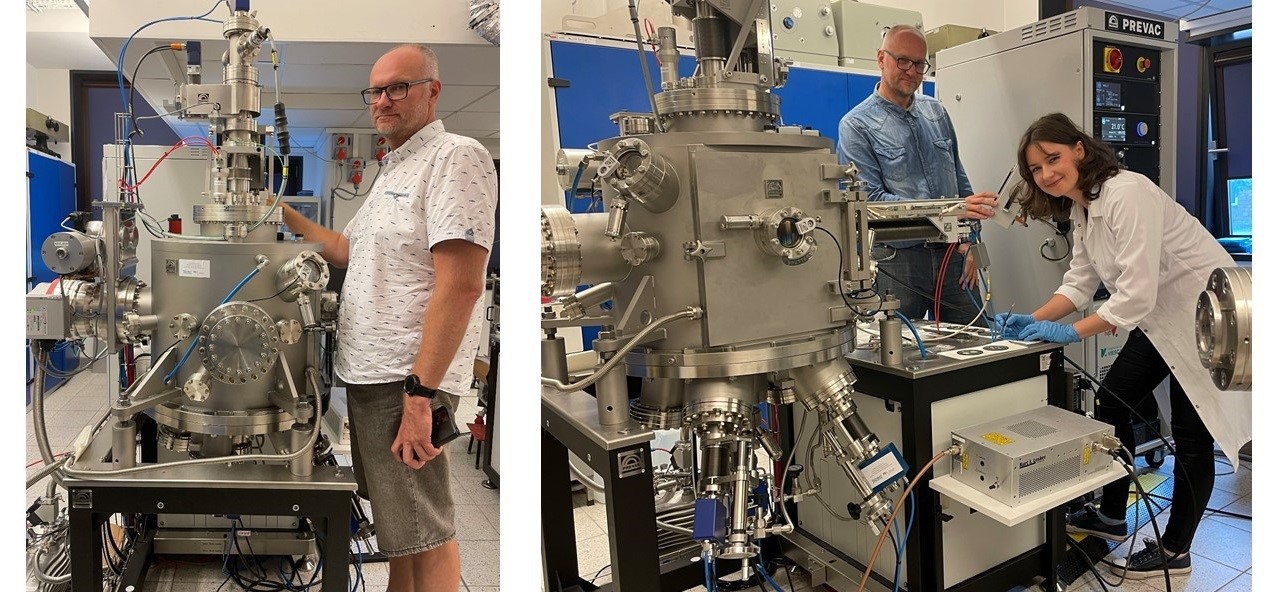

Scientists at IPPT PAN developed a new stand for the deposition of coatings by magnetron sputtering. Research team supervised by dr hab. Tomasz Mościcki is developing superhard coatings as part of the SUPERCOATS project – “New coatings to increase tool life in forging and extrusion processes”.

Processing and using hard and damage-resistant materials has been the focus of attention for thousands of years. Indestructible tools often saved lives and helped civilizations develop. Research of materials resistant to extreme conditions has never been more intense than now, their development drawing the attention of the industry and funds around the world. The current peak of interest results from an increase in efficiency, but also soon-to-be space travel. Moreover, there is a recent trend in replacing expensive and hardly synthesizing materials such as diamonds with cheaper equivalents. Commercially produced materials are often coated with thin layers that substantially improve their durability. The major problem with using a superhard and thermally resistant ceramic in the form of a protective coating is its brittleness and problematic adhesion to softer substrates. For this reason, recent research interests include elastic and hard ceramic coatings obtained by magnetron sputtering methods. Among them, tungsten diborides represent a new class of coatings which are superhard and, at the same time, have a high fracture toughness. Adding a transition metal (TM) such as titanium, zirconium or tantalum to WBx leads to a significant increase in the mechanical and tribological properties in comparison with non-additive borides and commercially-used nitrides and carbides. Even in the form of thin layers, tungsten borides have a high hardness (Hv> 40 GPa), a “metallic” electrical resistance 0,35¸1·10-6 Wm), and a relatively reasonable price, so they can be used for coating scratch-resistant surfaces, and in producing cutting tools. The most recent studies have shown that tungsten borides may as well be used in radiation shielding.

Die for extrusion of aluminium profiles

Since 2022, a team of experts lead by dr hab. Tomasz Mościcki (Department of Experimental Mechanics, IPPT PAN) has been developing superhard coatings as part of the SUPERCOATS project, “New coatings to increase tool life in forging and extrusion processes”. Their project aims at developing a new technology linking synthesizing discs by spark plasma sintering (STS) with the deposition of hard and wear-resistant coatings of ternary tungsten borides. The project assumed the purchase of a modern system for coating deposition by magnetron sputtering. It comprises a vacuum chamber, in-situ monitoring of coating thickness, a substrate heating system to the maximum temperature of 1000 °C, and a gas mixing chamber for reactive gasses such as oxygen, nitrogen, and hydrogen. The system can be equipped with 5 magnetron heads with a 2’’ diameter that can operate in both continuous or pulsed mode. Thanks to the induction of a high-power plasma plume, the use of modern HIPIMS power supplies creates new opportunities to, for instance, deposit materials such as DLC diamond coatings, which have so far been beyond the reach of magnetron sputtering techniques. In addition, the system has been equipped with a substrate manipulator allowing the deposition of coatings with several nm to several mm in thickness on elements with a 3’’ diameter. This new coating deposition system allows the deposition of pure metal layers, precise additions of materials, nitridation of samples, and deposition of chemically complex alloys such as high-entropy alloys. By controlling the process parameters such as pressure, temperature, the composition of deposited materials, and the composition of the reactive atmosphere, it is now possible to shape the microstructure and the phase composition of coatings. It is also worth noting that the magnetron sputtering technique allows a fast deposition of coatings with very low surface roughness. Thus, it can be used in both scientific research and industrial applications.