On December 16, 2021, the Main Board of Polish Materials Science Society awarded Mateusz Kopeć, PhD from IPPT PAN, for the best doctoral dissertation in the field of Materials Science defended in 2020. Dissertation title: “Hot stamping of titanium alloys”. Thesis supervisors: dr Liliang Wang, prof. Jianguo Lin and prof. Zbigniew L. Kowalewski.

M. Kopeć research was driven by demand for low density and high strength materials in the aviation sector which expanded greatly due to ambitious carbon emission and fuel consumption targets. In order to meet these targets, weight reduction via the use of lightweight materials was found to be mandatory. In the aerospace sector, high strength structural components are made from titanium alloys. However, the forming of complex-shaped components from titanium alloys is time, energy and cost intensive.

M. Kopeć research is mainly focused on the novel hot stamping process for titanium alloys using cold forming tools and a hot blank, which could be an alternative for conventional forming techniques. His work aimed to investigate the microstructural evolution and flow behavior of a titanium alloy (Ti6Al4V) under hot stamping conditions experimentally, and to model these parameters using the constitutive equations proposed. The material behavior was modeled using mechanism-based viscoplastic constitutive equations to replicate the material response of a two-phase titanium alloy Ti6Al4V under hot stamping conditions. Finally, the developed model's accuracy was validated by comparing to experimental uniaxial tensile tests and microstructural maps of the deformed alloy. The developed material model was implemented into the Finite Element (FE) simulation to study the deformation characteristics during the hot stamping process. The verified simulation data were analyzed through a novel hot stamping technique with good agreements achieved between the predicted and experimental results. A complex shaped wing stiffener panel component was successfully formed from TC4 titanium alloy, demonstrating the great potential of investigated technology in forming complex shaped titanium alloys components.

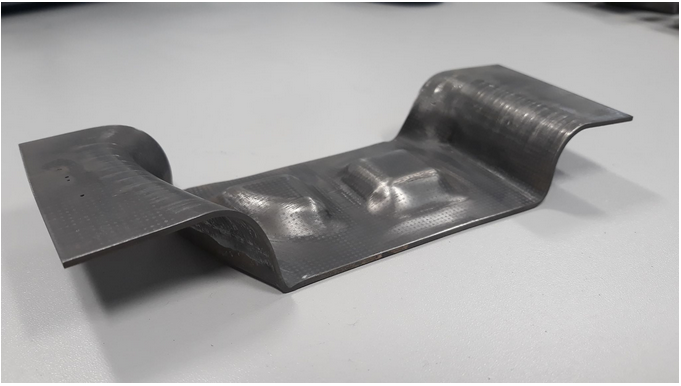

The technology implemented by M. Kopec – “FAST Fast Light Alloys Stamping Technology” – enables fast forming of titanium alloys and significantly decreases tools wear commonly found in the conventional hot forming processes. Due to its high efficiency and innovativeness, the process is becoming a competitive alternative to conventional forming techniques. The reduction of forming cycle by 1 second could further reduce the cost of production of a given component on one production line by 1 mln USD in a year. According to the market analysis and the results of published research, the implementation of the FAST technology may lead to an 80% increase in production efficiency with the simultaneous reduction in forming time from 6 minutes to just 1 minute. The research conducted by M. Kopeć during his PhD studies resulted in the forming of the world’s first full-scale wing stiffener component for airplanes (Picture 1). His research also confirmed that this part cannot be formed using current stamping technologies at a mass production mode.

World’s first full-scale formed wing stiffener component [1].

The research was conducted in close cooperation with the Aviation Corporation of China AVIC, an industrial partner that sponsored M. Kopeć’s research at the Imperial College London, and resulted in M. Kopeć’s receiving the PhD degree. Currently, M. Kopeć continues his research to increase process efficiency working as Visiting Scholar in the Metal Forming and Material Modelling Group of Imperial College London.

The thesis is available online via link:

[1] M. Kopec, Hot stamping of titanium alloys, Imperial College London, 2020 https://doi.org/10.25560/86389