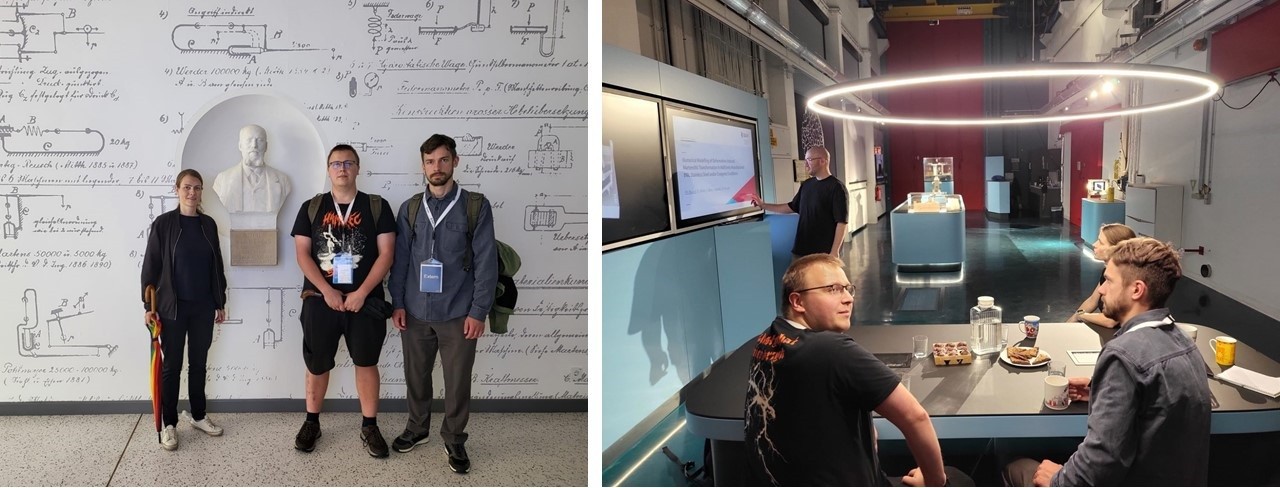

Recently, the team from the Department of Experimental Mechanics at IPPT PAN – Dr. Jakub Tabin, M.Sc. Eng. Adam Szyszko, and Eng. Hubert Nejman – visited BAM – the Bundesanstalt für Materialforschung und -prüfung in Berlin. This German federal research institute focuses on the analysis, testing, and certification of materials, chemical substances, and structures. Its origins date back to 1904, when Adolf Martens (1850–1914), a distinguished metallurgist, organized the Royal Material Testing Office (Königliches Materialprüfungsamt) in Berlin – an institution dedicated to examining the quality of metals and industrial products. Martens, a pioneer in the microscopic examination of steel microstructures, the originator of the term “martensite,” and the author of groundbreaking work in heat treatment, contributed to the development of modern steel production processes with controlled properties. Today, BAM continues this tradition, combining scientific research with the development of standards and procedures that ensure safety and quality across many industries.

Fig. 1 Daniela Schob, Adolf Martens, Adam Szyszko, and Hubert Nejman right after discussing whether deformation-induced martensite in printed steel exhibits the same features as in conventional steel.

Fig. 2 Illumination after Philipp Maasch’s presentation on the model of deformation-induced martensitic transformation in printed steels.

At BAM, we visited Dr.-Ing. Daniela Schob and her LoTempAM (Low Temperature Additive Manufacturing) team, who study how additively manufactured steel components can reliably operate under extreme conditions – including temperatures as low as –253°C and in compressed hydrogen environments. The group integrates PBF-LB/M manufacturing techniques, advanced experimental analyses, numerical simulations, and machine learning to comprehensively assess component durability and safety.

Fig. 3 The key is a big smile: from left – Jakub Tabin, Hannah Ruddick-Trentmann, Philipp Maasch, Adam Szyszko, Hubert Nejman, and Daniela Schob.

During our visit, we were shown state-of-the-art 3D printers using SLM technologie. We took part in a tensile test demonstration of additively manufactured 316L steel specimens, simultaneously exposed to compressed hydrogen and axial loading. We also reviewed the progress of our cooperation, and Philipp Maasch presented a finite element model of deformation-induced martensitic transformation in printed steel, validated using results obtained at the IPPT PAN Laboratory for Material and Structural Testing under cryogenic conditions.

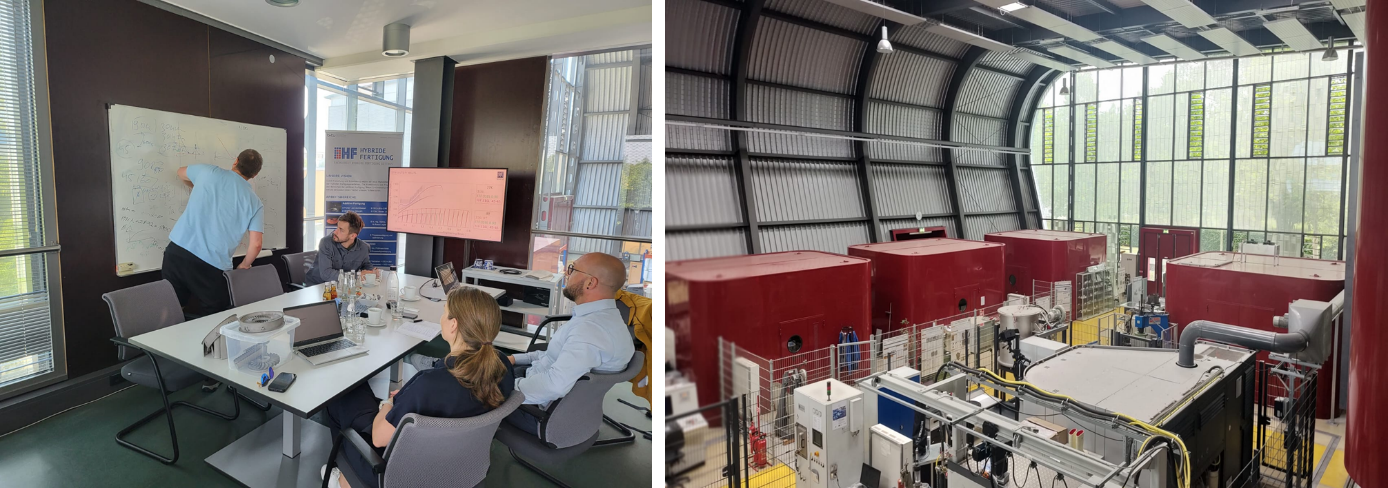

The next stop was a visit to the Fachgebiet Hybride Fertigung (FHF) at BTU Cottbus – a unit specializing in the development and optimization of hybrid manufacturing processes combining 3D printing and CNC machining. The FHF team conducts research on new materials and processes, develops 3D printing technologies for polycrystalline materials, and implements projects in cooperation with industry.

During the meeting with prof. Prof. Dr.-Ing. Sebastian Härtel, we discussed our latest research on the influence of pre-straining at cryogenic temperatures on the properties of printed materials and outlined directions for further collaboration. Students actively participated in the discussions, presenting analyses of the impact of dissipative phenomena on steel strength. We were also shown the Mobile Repair Factory (MORE) – a mobile repair facility developed in cooperation between BTU Cottbus-Senftenberg and METROM. The system is housed in a standard shipping container, enabling easy transport to remote plants and industrial zones. Inside is a hybrid machine tool (e.g., Metrom PM-800), combining additive technologies (3D printing using the DED method) and subtractive ones (milling, turning).

Fig. 4 “I’ll draw you the strain-induced martensitic transformation in a moment… I just need a piece of the board” (Adam Szyszko). On the other side: Hubert Nejman, Daniela Schob, and Sebastian Härtel (Head of the Hybrid Manufacturing Department at BTU); b) All the options under the sun … in this Hybrid Manufacturing Department at BTU, 3D printers in FFF, SLM, SLS, DED, etc. technologies..

Intense days full of attractions printed lasting and exceptionally pleasant memories in our minds.

The trip was carried out as part of the project Joint Research Projects between the Republic of Poland and the Federal Republic of Germany, aimed at supporting the mobility of Polish-German research teams. Project proposals were submitted in parallel by German partners to DAAD and by Polish partners to NAWA.

Link to the project description:

https://www.ippt.pan.pl/aktualnosci/wspolpraca-polsko-niemiecka